When buying a washing machine, buyers look not only at its technical characteristics, but also make a choice in favor of well-known manufacturers. The Italian brand Indesit is very popular in our country. This company produces various household appliances, including washing machines. Indeed, as practice shows, the equipment of this company is reliable in operation, but still malfunctions of the Indesit washing machine also occur. What breakdowns occur and how to fix them, this will be discussed in the article.

Features of the Indesit washing machine

Indesit is an Italian company producing household appliances. To reduce the cost of production, some factories were moved to other countries, but this does not mean that the quality of the equipment suffered as a result. The most important thing is not to stumble upon a Chinese counterfeit.

Electronics stores offer more than a hundred models of Indesit washing machines. Such variety can satisfy any housewife’s needs for washing linen and clothes.The washing mashines come in both full-size and very small, compact ones. There are models that can hold 7-8 kg of laundry. The average weight of dry laundry in machines is about 4-5 kg.

According to the type of loading, Indesit comes with a front and vertical hatch. The selection of control programs and control of washing is carried out using an LED display or light indicators and buttons on the panel if there is no display. For example, the BWE 81282 LB model has the largest display among machines of this brand.

The instructions indicate the service life of washing machines. As a rule, it does not exceed 7 years. This does not mean at all that the machine will fail 7 years after purchase. This message is for informational purposes only. The warranty on equipment is established by the manufacturer and is never less than 12 months.

The cost of Indesit washing machines starts at an average of 14,000 rubles.

Fault diagnosis

In the mode of constant use of the washing machine (washing 2-3 times a week), according to statistics, the first breakdowns occur in the 4th year of operation. This is the average figure recorded in service centers.

If there are no water leaks, there is no burning smell or smoke, the lights on the control panel are not blinking like crazy, and there are no errors on the display starting with the letter F, then most often the malfunction is not of any serious nature and will not cause much damage to your wallet. Having a little experience working with technology and understanding the principle of operation, it is even possible to fix the problem yourself.

Indesit equipment is equipped with an automatic self-diagnosis system. On washing machines equipped with a digital display, an error code will be displayed if there is a malfunction. Errors begin with the letter F followed by a combination of numbers.In some models, the error code begins with H. To decipher the error code, just look at the instructions or the Internet.

If the equipment does not have a display, then the malfunction can be determined by the combination of light indicators above the control buttons. This option is somewhat more difficult to diagnose, but also all possible combinations and a description of the malfunction can be found in the instructions. Housewives who often use such equipment will be able to understand by the blinking of the indicators that something has happened.

After deciphering the error code, it will be clear whether you can fix the problem yourself or whether it is better to contact a service center.

Washing equipment does not turn on

The hostess presses the “START” button and nothing happens. The first step is to check whether the machine is connected to the network. The plug may not be fully inserted into the outlet. Sometimes short circuit protection is triggered in this way. By plugging another device, such as a table lamp, into the outlet, check that it is working properly.

It's worth checking the water supply. Suddenly the pipe is blocked, or there is temporarily no water. Sometimes when you turn on the machine, nothing happens if the delayed start function is turned on.

If the machine responds to the choice of program, but when you press start the water does not fill, you should re-close the door. Most likely, it does not fit tightly, and to prevent leaks, the machine itself blocks its operation. If the machine has a display, then with the problems described above there will be an error F01 or F02.

When everything is checked, there is water and electricity, the door is closed, but the machine shows no signs of life, the control unit is faulty. Such repairs can only be performed by specialists. It is worth contacting the service center.

The drain system is clogged

Water drainage problem is the most common problem with Indesit washing machines. It manifests itself in the fact that water remains in the drum after spinning, and errors F05 or F11 may also appear on the display. The first error indicates that the water was not drained within a certain time interval. The second error occurs when the pump or drain pump fails.

Blockages are formed from small objects that come off the laundry during washing. These are buttons, fluff, threads, hair, etc. These items can break the impeller or block the motor if not contained by the filter.

The solution to the problem when the motor is blocked is to disassemble the pump and remove the item. In all other cases, replace the broken part - the pump.

To prevent problems with blockages, it is worth periodically cleaning the filter in your washing machine. It is enough to open the lower small hatch on the front side of the machine once every 3 months and unscrew the filter. The filter itself is made in the form of a cone with a mesh. It is necessary to clean its mesh structure and the place where it is installed with your hands.

Remember that the filter unscrews counterclockwise. Before starting the procedure, you should place a flat container or a rag under the bottom of the machine, as some water will flow out of the filter hole. Place the washed part back and close the door.

Bearing failure

This type of malfunction leads to problems in the operation of the washing machine drum. They manifest themselves in the form of poor rotation of the drum, creaking, other atypical sounds, hum or strong vibration of the machine. Over the years of operation, the bearing rusts, the lubricant wears off, and may even fall apart.You can repair the bearing at home, but you need to have a good understanding of how the machines work. Otherwise, you should trust the masters.

To diagnose and repair the bearing, you will need to remove the rear and top covers. This is the case if the machine has front loading. To get to the drum with the bearing, you need to remove the dispenser, control unit, and unscrew the holders. We insert the rubber cuff into the drum, remove the blocker, and now you can remove the front wall. We take out the counterweight, heating element, pipes and engine of the machine. That's it, now you can carefully pull out the drum with the bearing.

Remove the faulty bearing using available tools. It is better to replace the oil seal too. Lubricate the installation site with special grease and install a new bearing with an oil seal.

Reassemble the washing machine in reverse order. Experts recommend sealing all joints with sealant to prevent water leaks.

It is better to take replacement bearings of high quality, from trusted companies, so that this malfunction does not overshadow further operation.

Control module failure

The unit, or control module, is the brain center of the washing machine. It is he who gives the command when to fill and drain water, to what temperature to heat the water and when to turn on rinsing and spinning. The control unit is a board with a bunch of different microcircuits, relays and other things.

The control unit on washing machines with mechanical control fails much less often than in “sophisticated” machines with a digital display and control. In mechanical machines, the service life of the unit can be more than 10 years. This is due to the fact that the control unit itself has a fairly simple electrical circuit on the programmer.For machines of this type, programmer failure is the rarest malfunction. Performed by service center specialists.

For machines with an electromechanical control type, if the unit breaks down, the corresponding error F09 or F18 will appear on the display. Other signs of a breakdown of the control unit will be chaotically flashing indicators on the instrument panel, and a discrepancy between the washing time and the stated program. The time may be more or less than expected. Sometimes there is no spin at all, although the program provides for this.

Repairing such a control unit involves updating the firmware. But you won’t be able to carry out this procedure on your own. The specialist will update the firmware using the software, and replacement of the control unit will not be required.

Overall, the Indesit control module is very sensitive. You need to make sure that no moisture, drops of water, or sudden voltage surges get into it. When water droplets enter, the relays and capacitors rust and the electrical contact is lost. To prevent this malfunction from occurring, you should strictly follow the instructions for the household appliance. The repair in this case consists of the technician restoring the electrical contacts.

Replacing the control unit completely is carried out in rare cases.

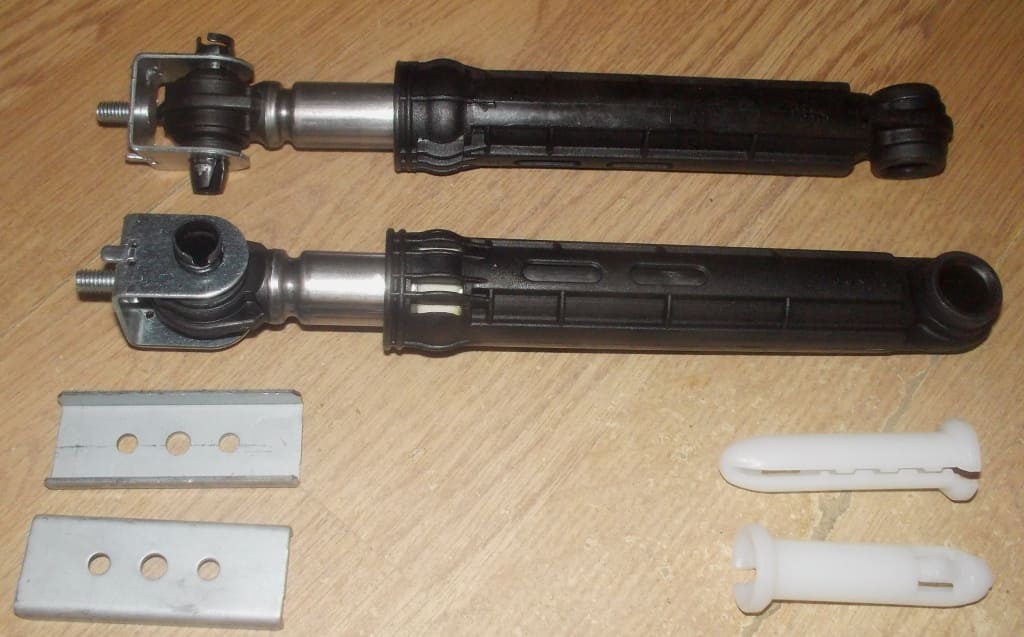

Malfunction of shock absorbers (dampers)

To reduce vibration emanating from the drum, shock absorbers or dampers are installed. They differ only in the presence of a return spring. The shock absorber has it, the dampers do not have a spring. Dampers in new models are installed more often than shock absorbers.

Failure of the shock absorbers manifests itself in the form of a strong rumble inside the washing machine. These parts can only be replaced in pairs.It is important to know that if a problem with the shock absorbers has been diagnosed, the device cannot be operated until the technician arrives.

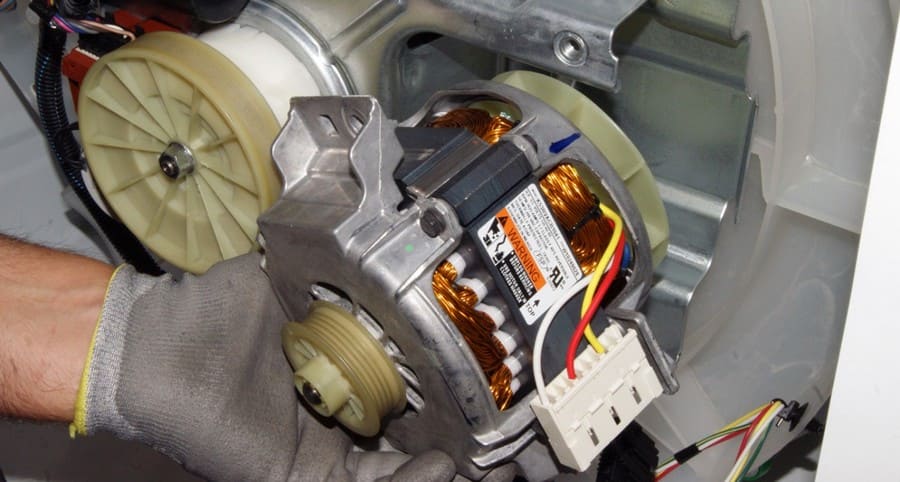

Electric motor is faulty

There are 2 groups of problems with the electric motor in the washing machine:

- The engine was completely burned out.

- Engine parts have failed.

In the first case, replacing the motor cannot be avoided, especially if there is a smell of smoke or burning. At the same time, experts working with Indesit note that, after all, complete engine failure is rare. The cause of the malfunction may be a short circuit in the winding or a break in the winding at the rotor.

In the second case, brushes, lamellas, rotor or starter windings inside the engine may fail.

Most often, the problem occurs with wear on the motor brushes. The reason is the constant operation of the washing machine. It manifests itself in the fact that when you click “Start” the program is not executed. Brushes are paired parts in the engine, and they are also replaced together. It is important to buy parts from trusted manufacturers.

If the wiring in the rotor winding has burned out, this will be clear when the drum stops rotating. At the same time, the remaining functions of the machine work: the lights are on, water is poured. For such repairs, you need to find a specialist to rewind the motor or install a new motor.

Dirty engine fins often cause problems. In this case, careful cleaning of these parts helps.

Problem with water supply to washing unit

There may be several similar problems, and they are associated with different parts of the washing machine.

First of all, you should make sure that the water supply is not temporarily limited or the pressure in the network is not reduced.

When drawing and draining water into the machine, you need the system to understand when the liquid reaches the desired level.The water pressure sensor is responsible for this. It is called a pressure switch. It measures the pressure in an empty and full tank. If the sensor simultaneously receives a signal that the tank is empty and full, then water will not be supplied. This occurs due to sticking of the sensor contacts. In this situation, replacing the sensor will help.

Only a specialist can determine the cause of such a malfunction, since the flow of water may be limited due to other components. For example, a control unit or electrical wiring.

The intake valve may also be faulty. It is responsible for filling the water to the required level and then shuts off the water supply. The housewife may notice this problem if the tank is not filled with water during the time allotted by the program. And also when the machine is not working, the tank is filled. On models with a display, error F10 or H20 will appear.

To correct the problem, you can try to clear the pipes and hoses from blockages; in extreme cases, you will have to replace the valve.

The mesh on the inlet valve can be kept in a solution of vinegar or citric acid to remove scale from hard water.

The washing machine is leaking

Leaks in the washing machine may be caused by damage to the rubber seal. This occurs from constant vibrations, washing objects with sharp edges, spikes or parts, and constant contact causing friction. If the rubber is not badly damaged, then it can simply be sealed and placed on the top of the hatch. There is no constant contact with water, and there will be no leakage. If the damage is serious, then it is enough to completely replace the rubber around the hatch. The cost of such repairs is small.

If everything is fine with the cuff and there are leaks, then you should clean the underside of the door from plaque and dirt. During operation, scale accumulates on the hatch, which interferes with the tight contact between the hatch and the rubber cuff. As a result, the owner sees streaks of water. You can clean it either with professional plaque removers or with improvised means. The main thing is not to rub the plastic with a hard or metal sponge to avoid scratches.

The heating element does not work

A tubular electric heater is used to heat water to a given temperature and function as a dryer in those machines that provide this. A non-working heating element on the display is most often indicated by error F08.

In the old generation Indesit machines everything was very clear. If the water does not heat up, then the reason is the heating element. But washing mashines of the last decade have become more “smart”, and there may be several reasons for the lack of warm water. This is a malfunction of the heating element, the temperature sensor, and the control unit. Sometimes even the reason may be in the pressure switch.

In most Russian cities, hard water flows from the tap. It is this that leaves a thick layer of plaque on the heating element. Because of this, thermal conductivity decreases and the water takes longer to heat up. Overheating of the element will lead to combustion of the coil and complete failure of the part. You can determine the malfunction by touching the plastic door. If the water in the drum is cold, then the problem has been found.

It is not possible to clean the heating element manually; it is better to replace it with a similar part. When purchasing, be sure to ensure that the power and other parameters are suitable for the washing machine.

It is recommended to use special products to soften water hardness.

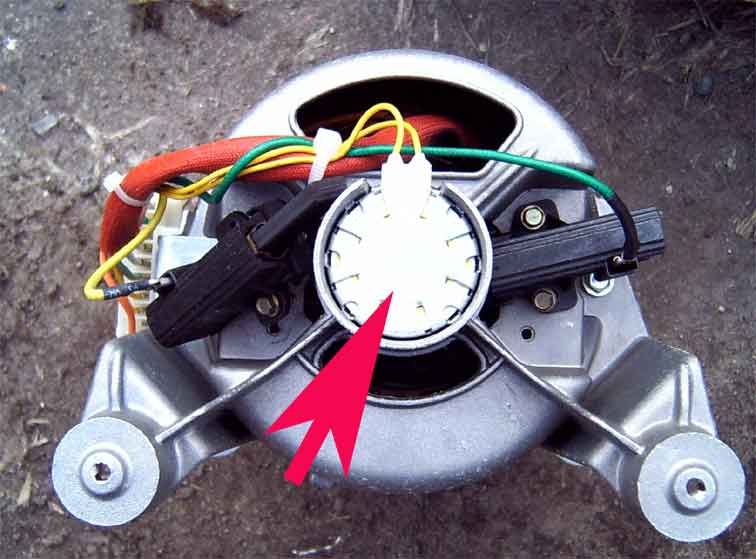

Tachogenerator failure

Manufacturer Indesit installs a tachogenerator on its washing machines. This is a special sensor that counts the spin speed. Looks like a metal ring with a starter.

A sensor malfunction can be detected if the number of spin revolutions does not correspond to the program. There can be either many or few revolutions. For example, 800 rpm is set, but the spin cycle is 1000 rpm. An experienced housewife will immediately notice the difference in her linen.

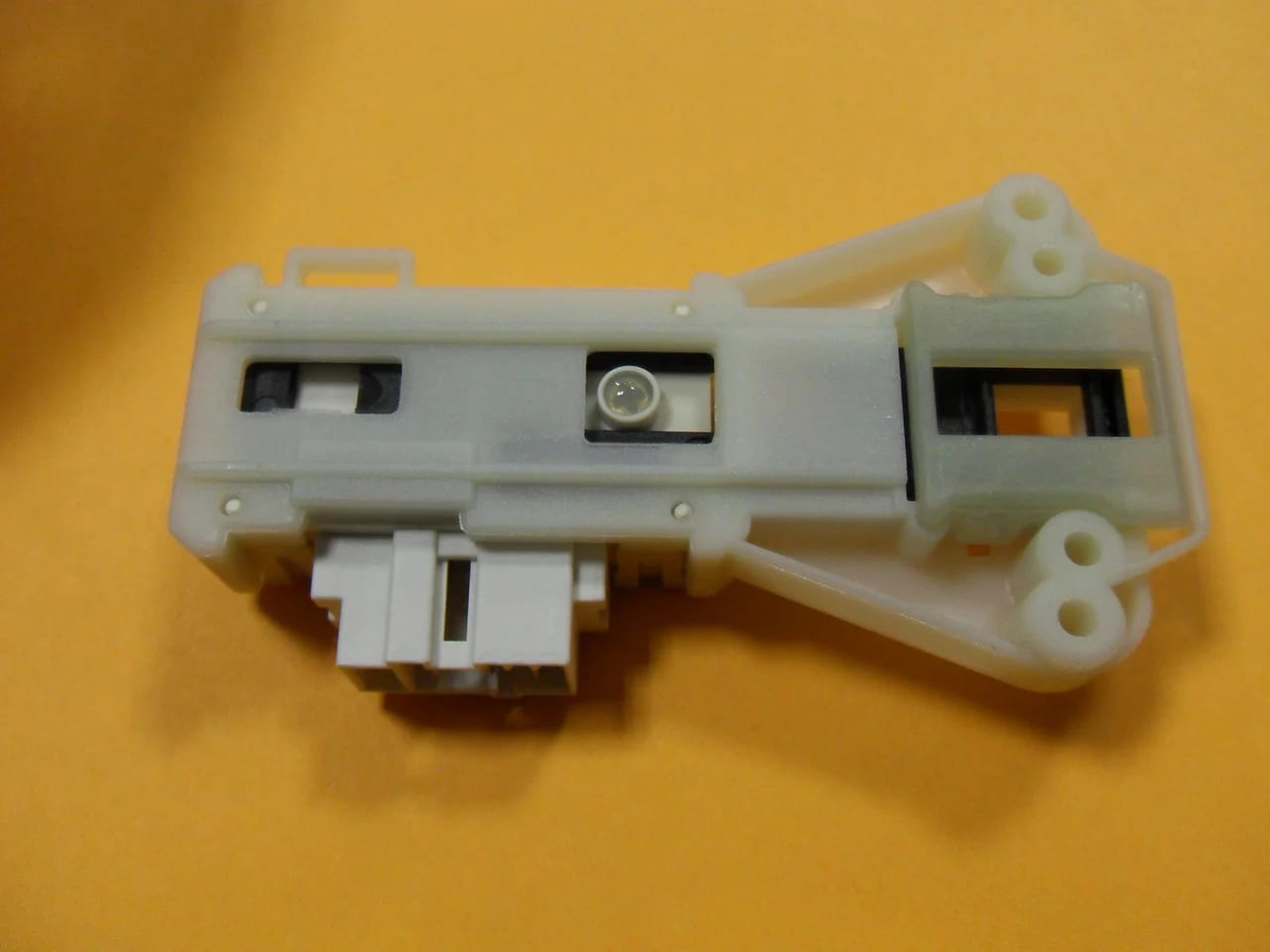

The hatch locking device is faulty

The hatch blocking device is necessary to protect the apartment from flooding during washing. Under normal conditions, when you press “START”, the system locks the doors and will not allow them to be opened until the entire washing process is completed.

The first step is to check how the washing machine door is closed. Perhaps it really doesn't fit tightly. In this case, re-closing the hatch will help. It is also worth inspecting the rubber cuff for the presence of foreign objects.

If you put a lot of laundry in the drum, the door may also not close. It is enough to remove excess laundry.

If simple actions do not resolve the issue and F17 lights up on the display, then there is a problem with the hatch locking device. This part must be replaced.

A malfunction, in addition to the occurrence of an error, can be determined by the fact that the door does not lock when the machine starts operating or, conversely, does not unlock after washing.

The rarest variant of the problem with the locking device occurs if the voltage in the network does not reach 220 V. Most often this is typical for private houses. This practically never happens in apartments.

Tips for repairing a washing machine

There is a group of faults in Indesit washing machines that you should not try to fix yourself at home. This includes electronics failure, bearing replacement and engine repair. Work to fix these problems requires special skills, tools and the qualifications of the master. It is not enough to simply disassemble the machine and remove the parts, you need to understand what and how to connect back so as not to damage the serviceable parts. Otherwise, you can make several faults out of one. This will subsequently affect the cost of repairs and the possibility of repairing the washing machine.

At home, having an elementary understanding of the structure and operating principle of household appliances, you can fix water leaks, problems with filling with water, difficulties with the supply of detergent or washing powder.

If a small amount of water appears on the floor after washing, then you should check the integrity of the hoses and pipes, and also check the rubber cuff. We are looking for possible abrasions or breaks. If something like this is there, then replacing the rubber parts is easy. A home craftsman can replace the belt responsible for the rotation of the drum.

The craftsman only needs 2 screwdrivers: a flat and a Phillips screwdriver, pliers, and a multimeter to ring out the parts.

It is best to connect the washing machine through a network filter or voltage stabilizer. This will help prevent breakdowns of the control unit and problems with the electronics during a sharp voltage surge in the network.

If a number error appears on the display, while a visual inspection does not reveal any problems, you should pull the plug out of the socket for 20 minutes. After reconnecting, there is a chance that the error will disappear.There is a group of breakdowns in Indesit washing machines that you should not try to fix yourself at home. This includes electronics failure, bearing replacement and engine repairs. Work to correct these problems requires special skills, tools and qualifications of a craftsman. It is not enough to simply disassemble the machine and remove the parts; you need to understand what and how to connect it back so as not to harm the working parts. Otherwise, you can turn one fault into several at once. This will further affect the cost of repairs and the possibility of repairing the washing machine.

At home, having a basic understanding of the structure and operating principle of household appliances, you can fix water leaks, problems with filling water, and difficulties with supplying detergent or washing powder.

If a small amount of water appears on the floor after washing, you should check the integrity of the hoses and pipes, and also check the rubber cuff. We are looking for possible abrasions or breaks. If there is something like that, then replacing the rubber parts is easy.

A home craftsman will be able to replace the belt responsible for rotating the drum.

As for the tools, it is enough for the master to have 2 screwdrivers: a flathead and a Phillips, he also needs pliers and a multimeter for ringing parts.

It is best to connect the washing machine through a surge protector or voltage stabilizer. This will help prevent damage to the control unit and problems with electronics during a sudden power surge.

If a number error appears on the display, and a visual inspection does not reveal any problems, you should unplug the plug from the socket for 20 minutes. After reconnecting, there is a chance that the error will disappear.This occurs due to a power failure.

If any problems arise while operating a washing machine that is under warranty, it is better not to try to fix the problem yourself. You should contact the service center to maintain the warranty. Moreover, warranty repairs are carried out free of charge.

Conclusion

By following all the instructions in the operating instructions for the Indesit washing machine, the user will be able to wash for many years and not experience any problems with household appliances.

It is not recommended to wash several cycles one after another without a break. After each wash, you should let the machine rest for about an hour and only then start a new wash.