The control module is one of the most vulnerable systems in washing equipment. Repairs to the control module of a washing machine should be carried out in workshops, especially if the unit is under warranty. But if the warranty period has expired, you can fix the machine yourself, saving your own financial resources.

The control module is one of the most vulnerable systems in washing equipment. Repairs to the control module of a washing machine should be carried out in workshops, especially if the unit is under warranty. But if the warranty period has expired, you can fix the machine yourself, saving your own financial resources.

Principle and features of work

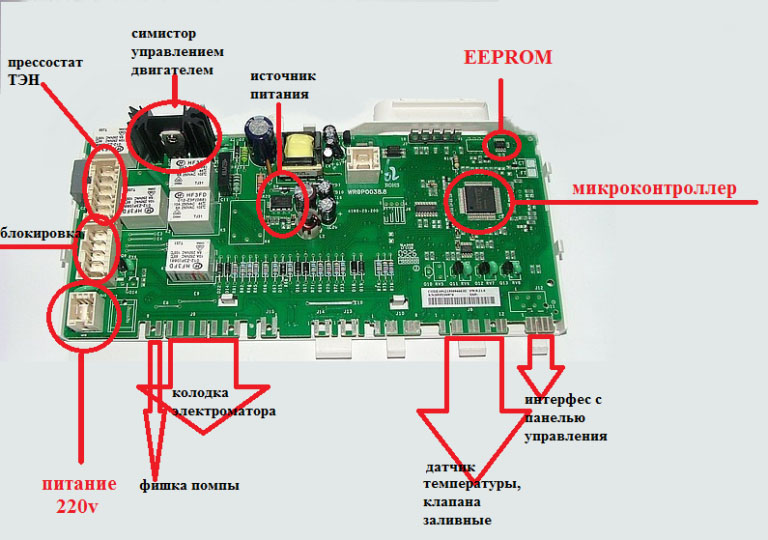

The control module is essentially an electronic board. Depending on the incoming signals from the sensors, this board activates one or another function. Moreover, this part is universal. The same control module model can be used on units from different manufacturers. However, the firmware of the board's central processor and the number of input/output signals differ depending on the year of manufacture a specific washing machine model.

The main tasks of the control module are:

- temperature control;

- control of the operation of the electric power unit;

- setting the washing cycle program;

- control over the operation of automatic blocking;

- ensuring control over inlet water pressure level;

- monitoring the correct functioning of drain pumps.

Causes of control module failure

The main reasons why this part of a washing machine fails are:

- Manufacturing defects. This happens extremely rarely, but it still happens even with well-known brands. Factory defects can be determined visually, for example, in the presence of poor-quality soldering of contacts, as well as by flux build-ups and peeling tracks. If the unit is under warranty, then you should not dismantle the control module yourself, but it is better to immediately contact the warranty service to replace it. The defect appears quite quickly within a few weeks after the start of its use;

- Sudden changes in the power supply. Perhaps this is the main reason why the control module of a washing machine fails. The voltage level that must be observed is usually indicated in the operating instructions for the unit;

- Non-compliance rules of technical operation of the washing machine;

- Water or moisture entering the electronic system. Many washing machine manufacturers strive to eliminate the possibility of moisture getting into the electronic board. Quite often, to achieve these goals, the control unit is filled with compound and the board becomes sealed. If you start the washing machine with a “wet” circuit board, the control of the unit will be blocked.

Water most often gets into the control module when the machine is operating in emergency mode or when it is moved.

Main signs of control module failure

There may be several symptoms indicating the need to repair the electronic board, the main ones being:

- washing machine won't start, error codes are displayed on the screen;

- flickering LEDs on the washing machine panel;

- the washing cycle differs from the set program;

- incorrect functioning of one or more programs;

- the washing machine does not wash, doesn't dial or does not drain the water;

- the washing cycle differs from the user-specified program;

- no spin or heating water.

DIY washing machine repair

Dismantling, as well as repairing the module, is not particularly difficult. All that is necessary is to remove the front panel and get to the installation location of the board. After which it can be easily removed.

Modern modifications of washing machines are designed in such a way that the terminals of the control device cannot be installed in the wrong position, which greatly simplifies the task. However, when performing dismantling work, you must remember what is connected where, so that you can later put everything back together without any problems.

However, there are times when it is better to entrust the repair of the control board to a professional.

The main signs that it is better to contact a specialist are:

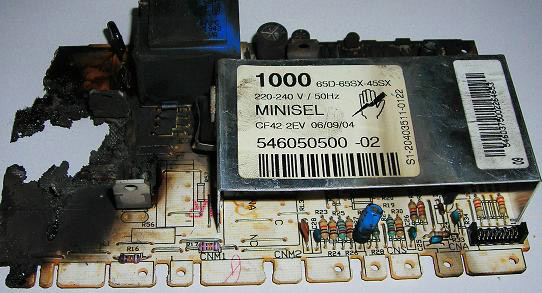

- on the electronic board there are places of discoloration in the form of scorch marks and darkened tracks;

- capacitor caps are broken (usually in the place of a cross-shaped notch) or clearly convex;

- darkening of the main processor installation site;

- areas of burnt-out coating are visualized on the damping coils;

- The legs of the microcircuit have a non-uniform color.

When is self-repair possible?

Do-it-yourself electronic board repair without the involvement of specialists is possible in case of the following breakdowns:

- Malfunction of control sensors. As a rule, this breakdown occurs due to clogged or greasy contacts in the adjustment knob. Signs of damage:

- Malfunction of the programmer sensors. Mostly occurs due to clogging and clogging of the contacts in the adjustment knob. Main symptoms: the regulator rotates quite tightly, there is no distinct click when it rotates. To eliminate the breakdown, clean the regulator knob.

- Presence of soot. As a rule, this applies to old units. Carbon deposits usually accumulate on the filter power coils. You can fix the problem with a brush or a regular rag;

- Malfunction of the sunroof lock sensor. Mostly occurs due to its being washed out or salted. Cleaning it is also enough to resolve the issue;

- The machine does not start or the drum speed is unstable. To eliminate this damage, it is necessary to tighten the pulley;

- The metal part of the washing machine is electrocuted, as a result of which the control module may block the operation of the unit. To solve such a problem, you should ground the washing machine.

Repairing a washing machine in a service center

Professional repair of the washing machine is necessary if there are serious breakdowns in the electronics, power unit, or if the owner does not have enough knowledge to fix them.

The cost of such repairs will depend on the following factors: the brand of the machine, the complexity of the breakdown, the need to replace structural parts, the urgency of the order. When repairing such household appliances, they are diagnosed, disassembled, replaced faulty parts, reassembled and test run.