A washing machine is a reliable and valuable assistant that has served us for many years. Without it, housekeeping is unthinkable, so we are very upset if the device breaks down. However, you should not be upset, since this technical tool can easily be converted into another functioning device that can be successfully used on the farm. There are many ideas on how to use an outdated or broken machine. What can be made from an old washing machine, how to implement the plan, what parts are needed for this, and is it possible to build the device on your own?

Where to put old washing equipment?

It often happens that it is easier to purchase a new washing machine than to repair an old one. Sometimes we want to update our household appliances, so we buy modern, improved products. Having installed a new device in the house, we have a question: what to do with the old one? It can be handed over for recycling, in which case you will have to pay additional funds for removal.

A washing mashine in working condition can be sent to a nursing home or donated to those in need. You can also apply to sell a used washing mashine and win a certain amount. Often, large shopping centers organize promotions where you can buy a new washing machine to replace the old one with an additional payment.

This is also a very convenient and practical option. However, in many cases, old equipment can find a second life on the farm. From the parts of the device, craftsmen make construction equipment, garden furniture and various devices for the garden, which simplify life. From a machine drum, for example, you can build an excellent outdoor shower or washbasin. It can also be used as a flowerpot. Housewives manage to use a container removed from an old barrel machine as a sterilizer or juicer. Also, using parts removed from the old apparatus, a potter's wheel is obtained, on which you can make a variety of clay crafts.

In general, a failed product can be disassembled into elements, which will subsequently become the basis for new useful devices used in the household. What parts can be used? This:

- Engine. Applies only if it remains operational.

- Drum. It is made of durable stainless metal and is quite a spacious container.

- Doors with impact-resistant glass. Used as an interior element. Provide reliable tight closure.

- Frame. It is also used to make many useful things for the home.

- Counterweights. They are usually made of cast iron.They can always be sold for scrap metal, but a more practical use is as a press for pickling cabbage.

- Wheels and legs. If necessary, they can be installed on a sofa and other pieces of furniture.

- Analog board. It contains many elements that are used to repair other household appliances.

- Other details. Springs, bearings, wires, and clamps are sure to come in handy in everyday life.

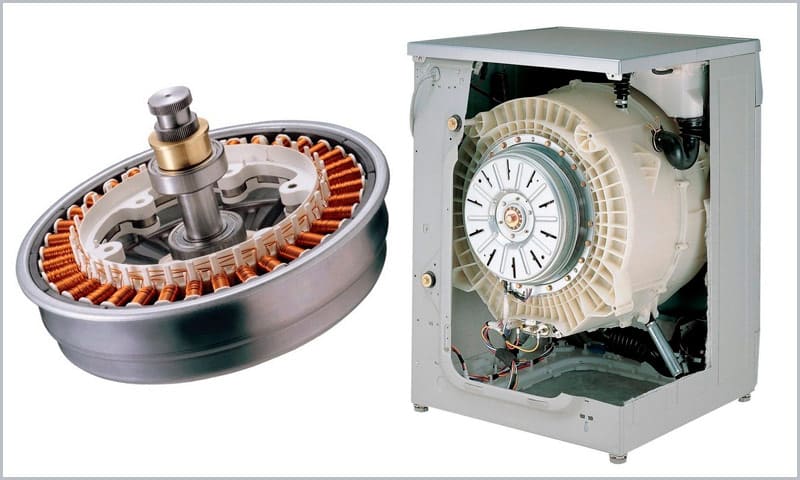

Types of washing machine engines

Before you start inventing new designs, you should study what the components are - parts removed from old devices. The main mechanism of any washing machine is the engine; without it, operating an electrical appliance is unthinkable. The washing unit is equipped mainly with the following types of motors.

Asynchronous

There are two types of such devices. Two-phase motors are found in older washing mashine models. More modern copies are equipped with three-phase asynchronous motors. The design of motors of this type is simple; they reach speeds of up to 2800 rpm and operate almost silently. The motor removed from the old unit can be reused. It is enough just to lubricate the bearings.

Collector

Present in most equipment models. Its main feature is that it allows you to adjust the number of revolutions. However, compared to the previous model, it is noisier. The product operates on both AC and DC current and is compact in size. The disadvantages of this design include rapid abrasion of the brushes. However, if necessary, they can be easily replaced.It can also heat up and even spark.

A similar motor is present in almost all modern automatic machines. These are reliable, durable, and practically unbreakable units. They can be used in devices subject to excessive loads. They have small dimensions and weight, so they are used to make small-sized homemade products. The products have high efficiency and are effective in operation. The design does not provide for the use of quickly wearing or breaking parts. The rotation speed can be changed.

Having determined the type of motor, you can figure out where to reuse it. However, before that, let's take care of disassembling the equipment. We carry out all manipulations extremely carefully, without undue haste. After a long work, there may be a coating on the parts of the device, which is carefully cleaned off.

Connecting a motor from an old washing machine

The operation of an electric motor is impossible without power. However, to avoid unpleasant incidents, you need to connect the wires correctly. Before disassembling the motor, you should pay attention to how it was connected in the previous diagram. To activate the motor, it is necessary to find the paired windings. To determine the terminals, you can use a tester. Set it to the resistance measurement mode. Connect the tester probe to the stripped contacts and record the readings. Consider that the resistance of the working winding - OB is always lower than the starting - PO. It should be noted that in the circuit, instead of the contactor SB, there may be a small capacitor.

After this, do the following:

- Install the motor on the surface, provide it with a safe position, since it will begin to vibrate in the operating state.

- We supply electricity to the excitation winding, at the moment of startup, press the SB button and hold for 2 seconds.

- If the motor is running normally, it will not overheat. Otherwise, we look for the cause of the malfunction and eliminate it.

- To change the direction of rotation, swap the wires.

What can be done from an old washing machine

The design of a washing machine contains many components and mechanisms that skilled craftsmen use to make homemade products. The machine body, engine, drum, pump, relays and switches can become elements of new devices that are used in everyday life. What can a used washing machine be converted into, and what needs to be done for this?

Grinder

This is the simplest device that even a beginner can make. Any household cannot do without it; it will help sharpen knives, garden tools and other tools. To make a sharpening machine, you need an electric motor from a washing machine; the motor of a miniature “Malyutka” model is also quite suitable. If you are using a high-speed motor, then you should not reduce the speed. It is more expedient to additionally construct a block with a shaft that will receive torque through a drive with a reduction factor.

The mount for a homemade device requires special attention. It must be reliable, since during operation the unit experiences excessive loads and vibrations. As a base, you can choose a wooden or metal surface on which the motor is fixed using clamps or brackets. A layer of cardboard or rubber is placed between the base and the working tool to dampen vibrations.In general, the manufacture of a sharpening machine consists of the following steps:

- We attach the engine to a small board or sheet of metal. The fixed homemade device can subsequently be moved and installed anywhere.

- When using an asynchronous motor removed from an old drum-type washing machine, we pay attention to sealing the structure. Dust, moisture, and particles of material can easily get into the mechanism, so we cover the engine with a strip of galvanized steel.

- We make an adapter attachment for the shaft. To do this, we weld pipes of different diameters. The diameter of one end should correspond to the diameter of the grinding wheel seat, and the other to the dimensions of the motor shaft.

By slightly re-equipping the manufactured tool, you can use it as a cutting machine or drum grinder. By the way, the switch can also be removed from an old washing machine.

Concrete mixer

Sometimes on a personal plot it is necessary to fill paths, build a foundation for a fence, or perform other work using cement mortar. In this case, you simply cannot do without a concrete mixer. It is not profitable to purchase specialized equipment in a store for one-time work. Well, it’s quite possible to make such a unit from improvised means. To make a homemade compact device, a cylindrical machine is suitable; it is also called a “barrel”. An old machine can easily be converted into a manual or electric concrete mixer. To do this, the activator located at the bottom of the container must be replaced with a shaft of a suitable size. We proceed as follows:

- We remove the activator.

- We cut out and weld the blades from a metal sheet.They should be U-shaped and about 5 millimeters thick. We will need two pairs of blades located perpendicular to each other. We install them instead of the activator using welding.

- We seal the drain hole of the machine hermetically.

- If you plan to work with large volumes of solution, it is advisable to update the motor.

- To reduce the speed of rotation, we install a gearbox in place of the belt drive.

- For ease of movement, we weld a metal frame with wheels to the device.

You can also successfully use washing machines with fixed blades, in which the solution is mixed due to the movement of the drum. This design is more efficient.

The manufacturing process requires some skills from the master, but a homemade product helps save time and effort on preparing the solution.

Feather removal machine

Owners of large households and those who breed poultry for further sale on the market cannot do without this device. The machine plucks the bird carcass efficiently and quickly. Factory devices operate on the same principle; the only difference between homemade devices is their less aesthetic appearance. However, by making your own pen removal device, you can save a lot. It is done like this:

- We install a disk at the bottom of the tank, the diameter of which is 1 cm less than the internal diameter of the container. The thickness of the disc should be about 3 mm. We mount it on the drive shaft.

- First, we drill holes in the disk into which we insert rubber fingers. These parts are the most expensive, but without them it is impossible to operate the future structure.

- We also drill holes in the side walls and insert rubber fingers into them. In total you will need about 120-150 of these elements. Their diameter depends on the type of bird for which the machine is made. A step of 3-4 centimeters should be provided between the holes. The first row of holes is made at a distance of 15 centimeters from the top edge of the body.

- There is no need to seal the drain hole. Excess moisture from the carcasses flows out through it.

The pen removal process is as follows. A poultry carcass scalded with boiling water is placed in the middle of the unit. The motor turns on and the rubber fingers remove the pen cleanly and quickly.

Grill

Many of us will not refuse delicious food prepared in nature. Food baked over a fire is very tasty, aromatic, and gatherings in the fresh air will bring a lot of pleasure. There is absolutely no need to spend fabulous sums on purchasing a factory grill. If an old washing machine is lost in the house, you can make a device for preparing a variety of dishes yourself. We take the drum of the machine, to which we first attach small legs. Small diameter pipes, which we carefully cut, will serve as legs. It should be noted that the steel material used to make the cases is durable and reliable. It is not afraid of heat, hot coals, or open fire, so it can be safely used.

To make the structure, a segment is cut out at the bottom of the tank. The segment angle is approximately 30 degrees. If you use a dial as an analogue, then you need to cut out the segment located between 17 and 19 hours.A hole is made in the side of the body into which the motor from the spit of the gas stove is inserted. A similar device can be purchased at any hardware store. The device works as follows: a carcass is placed on a spit, the motor is turned on, and a homemade grill is placed on the coals. After 40-60 minutes, the chicken with a golden brown crust is ready.

Doghouse

Parts from a broken washing machine can be used to create a dog house. For this purpose, use a hermetically sealed door. By attaching it to the dog's house, you can isolate your pet from wind, frost or strangers. However, in this case, care should be taken to ensure proper ventilation so that the animal does not suffocate. Small holes are made in the housing so that fresh air constantly flows inside.

Lawnmower

Designing a grass cutter from scratch is quite difficult and requires special skills. If you already have an old lawn mower with a broken motor, you can easily replace it with a working one removed from the washing machine. Well, if there is still a need to make a new device, we perform the following sequence of actions:

- We prepare a small platform and attach four small diameter wheels to it.

- We make a hole in the platform for the shaft. The motor is fixed to the base.

- The knives are mounted on a shaft at the bottom of the platform. To prevent grass from wrapping around them, we bend the cutting elements down a little.

- We attach handles to the homemade device, as well as a lever for turning it on and off.

The assembled structure will cope with the task in a small area.The electric model is supplied with a cord and connects to the nearest power source. If an asynchronous model is used, the product will be silent. Do-it-yourself lawn mower It will last for many years and will turn out to be a very useful device in the household.

Wax melter

Apiary owners will certainly like the idea of transforming a washing machine into a steam device for obtaining wax from bees' honeycombs. The simplest steam engine is a barrel that is filled with water and placed on a stove. Place a stand and a bowl with high edges at the bottom of the container. The wax raw material is suspended inside the container above the bowl. When it comes into contact with steam, it melts and flows down.

Tanks removed from old activator-type washing machines can be successfully used as a chamber for wax raw materials. To do this, the bottom of the tank is cut off and a stainless steel grate is welded in its place. You can also make several holes in the lower part of the body, and seal all other gaps. The water reservoir is a regular 40-liter saucepan, and the melted wax will flow into a bowl, which is placed on the ribs in the saucepan. It is important that it is firmly fixed. Holes are also made along the edges of the bowl to allow steam to pass through.

The entire structure consists of the following elements: a saucepan with a bowl, on top of which a washing machine tank is installed. It should fit a few centimeters into the pan. The frames are unloaded into it, and under the influence of steam, the wax flows into the bowl. The loading chamber turns out to be quite large, so up to 25 frames are processed in one go.

Brazier

There is no limit to the ingenuity of craftsmen, and many of them have adapted to using the drum of a washing machine to prepare delicious dishes. The metal used in the units is of very high quality, the thickness is also significant, so the homemade product does not burn out. The appearance of the grill is amazing, it has an attractive shiny smooth surface, so it will look great on a summer cottage or the territory of a country house. Craftsmen who are already using such an invention claim that it is more durable than analogues made in industrial enterprises.

We make the grill as follows:

- We prepare the base for the device. For this purpose we use a durable metal surface.

- We make a window in the side of the drum using a grinder.

- We construct legs from a metal pipe of small diameter, screw or weld them.

Thanks to the perforated surface, the combustion process will be more active, since oxygen freely enters the chamber. The skewers are placed on a roasting pan; for convenience, you can build several guides. We weld them together using welding.

A circular saw

Using a motor from an old washing machine, you can make a homemade circular saw. The main thing is to equip the motor with a special unit that regulates the speed. Without it, the product will work unevenly and ineffectively. Such a saw is not designed to perform complex tasks; it can cope with sawing boards whose thickness does not exceed 5 cm. It will not withstand enormous loads, so it is suitable for home workshops where one-time work needs to be performed.

All components of the device are laid out on a chipboard base.To make a saw you will need brackets, a saw blade, and a V-belt. The principle of operation is as follows: the engine drives a shaft, which is equipped with a small pulley. By means of a drive belt, the movement from the small pulley is transferred to the large pulley with the circular saw.

Before connecting the product, it is important to make sure that all parts are securely fastened. When working, you should work extremely carefully so as not to injure your hands.

Generator

Not everyone can handle assembling a generator, but those craftsmen who manage to implement this idea will be able to organize uninterrupted operation of household appliances even during a power outage. The device will not be powerful, but quite suitable for home needs. To turn a washing machine motor into a generator, you need to disassemble it and partially cut off the core. The remaining part contains grooves for neodymium magnets. The space between the magnets is filled by cold welding. To implement your plan, in addition to the motor, you should use other components: a battery, a current rectifier and a charge controller.

Animal feed cutter

A device for grinding feed will save the villager from a lot of trouble. A feed cutter helps grind root vegetables, corn cobs, and prepare homogeneous feed mixtures that are easier for animals to digest. You can make a similar device from an old washing machine using a drum and a motor. At the bottom of the device we install cutting elements in the shape of a propeller. You can cut knives yourself from an old saw. We connect them to the shaft using reliable fasteners.As you use the device, you need to ensure that they are always sharpened.

We cut a hole in the side to release the crushed food. We install a lid on the top of the device to prevent food from falling out. The lower part is equipped with supporting elements. They must be stable so that during operation the device does not sway due to vibration and can withstand the load. You can build a special platform that will give the structure reliability.

Wood lathe

Using a homemade lathe, you can grind workpieces, make holes in them, and cut wood. However, it is not so easy to do. When starting to make a device, you need to be patient and have some free time. First of all, a base is constructed to secure all parts of the product. Next we do this:

- Using corners, we attach the motor to the base.

- Using the corners, we make, assemble and attach the tool rest.

- We fasten the tool rest to the rear beam.

- We make an attachment for the shaft, for this we use a piece of metal pipe. We cut out the teeth using a grinder.

- We weld the nozzle to the shaft.

- Connect the power supply to the motor.

When performing turning operations, the workpiece is mounted on the teeth and rotating shaft of the rear beam.

Interior elements

Some parts of the washing machine can be successfully used in interior decoration. A drum, for example, makes an interesting coffee table that fits into the high-tech style. The tabletop of the product is made of MDF or plexiglass. Interesting models that use ceramics or epoxy resin for decoration. You can place an LED garland inside.Rays of light penetrating through the perforated surface will look amazing and create a festive atmosphere in the house.

The tabletop of the product is made of MDF or plexiglass. Interesting models that use ceramics or epoxy resin for decoration. You can place an LED garland inside.Rays of light penetrating through the perforated surface will look amazing and create a festive atmosphere in the house.

The drum also makes comfortable seats. The side surface is painted or covered with fabric that fits into the overall style of the interior. If desired, the side parts can be painted. The seat is cut out of chipboard and attached to the base using furniture hinges. We fix a comfortable pillow in a bright cover on top of the seat.

A small drum makes interesting chandeliers or floor lamps. In this case, the design should be supplemented with a special fixing device for the cartridge and the wiring should be connected. To do this, cut out a circle with a diameter half the diameter of the drum. It can be made from any metal. We fix the circle on the back wall, and in the center we make a hole for the cartridge. The lamp can be secured to the ceiling using cables. In this case, three hooks are screwed into the ceiling. You can decorate your design invention in any way, guided by your own taste and interior features. Products decorated with wine corks or upholstered in beautiful fabric look interesting.

Owners of fireplaces or old Russian stoves use the drum structure as a firewood rack. Moisture will not accumulate inside, as the holes ensure good ventilation. All that remains to be done is to attach the original legs to the product.

The machine door is used to construct an airtight window in the bathhouse. To do this, just cut a hole of the required size and fix the element.

In general, there are a lot of ideas for using old washing machines.Armed with imagination and free time, you can figure out on your own exactly how to use the old equipment. Therefore, do not rush to throw away or take a failed unit to a scrap metal collection point. A device that has spent its life can be used for other purposes, turning it into an effective and useful device in the household. Assembled with your own hands, it will undoubtedly last a long time and will significantly save money.

In addition, from a used washing machine you can also construct:

- router,

- irrigation pump,

- grass cutter,

- electric bike,

- honey extractor,

- Potter's wheel,

- wood splitter,

- concrete mixer,

- lathe,

- juicer,

- circular

- and much more.