Have you noticed that in your household appliances for washing clothes? the drum stopped rotating? We recommend that you urgently take appropriate measures to identify and eliminate the malfunction. The reasons for tank braking may be problems related to the performance of the water heating element, electric motor, drive belt, or device electronics. In order not to act spontaneously when identifying the reasons why the Zanussi washing machine does not spin the drum, we recommend that you consistently check all the most typical causes and eliminate the obstacles that prevent the drum from rotating freely.

Have you noticed that in your household appliances for washing clothes? the drum stopped rotating? We recommend that you urgently take appropriate measures to identify and eliminate the malfunction. The reasons for tank braking may be problems related to the performance of the water heating element, electric motor, drive belt, or device electronics. In order not to act spontaneously when identifying the reasons why the Zanussi washing machine does not spin the drum, we recommend that you consistently check all the most typical causes and eliminate the obstacles that prevent the drum from rotating freely.

So, we offer instructions for diagnosing and repairing a Zanussi washing machine that does not rotate the drum well.

Symptoms of malfunctions, probable causes of their occurrence

Drum stoppage may occur at any operating stage - when starting the machine, in the middle of the washing cycle or during the spin cycle. The failure of the drum to rotate occurs gradually or instantly, and this depends on the specific model of the machine, the malfunction that occurred, and the speed gained by the electric motor.

Certain symptoms will help you recognize the problem:

- the tank is filled with water, but the drum does not start to rotate;

- the lights on the panel light up, but there is no liquid intake;

- The washing machine is ready to start the cycle, the motor is running, but the drum refuses to rotate.

This behavior of SMA cannot be immediately explained. Moreover, the most typical reasons why a Zanussi washing machine stops rotating the drum number up to a dozen:

- the drive belt has fallen off, broken or weakened;

- a foreign object entered the tank of the car;

- the bearing is jammed;

- motor brushes are worn out;

- there was a breakdown in the motor;

- the water heating element has failed;

- the management module has ceased to perform its functions;

- the condensate broke down.

Priority measures

So, what should you do if your Zanussi washing machine stops spinning the drum? First of all, disconnect household appliances from the electrical network. Please note that at this moment it is prohibited to touch the body of the machine so as not to receive an electric shock. After this, the water supply is turned off, and wait ten to fifteen minutes until the liquid in the tank cools completely.

Please note that at this moment it is prohibited to touch the body of the machine so as not to receive an electric shock. After this, the water supply is turned off, and wait ten to fifteen minutes until the liquid in the tank cools completely.

Absolutely forbidden:

- restart the equipment;

- try to find out the failure while the unit is operating;

- try using the buttons on the panel to cause the drum to move.

Checking the drive belt

This is what causes most of the problems that cause the machine to stop rotating the drum. Due to long-term use, untimely replacement or defects during assembly, the belt can weaken, break or break. This is also affected by the constant overload of the tank. On one's own the drive is fixed without any problems:

- the washing machine is disconnected from all communication systems;

- the unit extends to the middle of the room so that there is free access to any side of it;

- the back panel is removed;

- the belt is inspected for damage, after which it is removed by turning the pulley by hand;

- installation of a new analogue is carried out first on the motor shaft, then on the pulley;

- At the same time, the condition of all parts around the pulley is checked. Replacement is carried out if necessary;

- the housing panel is installed in its place;

- A test run of the quick wash cycle is performed.

We get foreign objects

So, the belt is in perfect order, let's move on to checking the drum. It is likely that a small object in the form of a clothing button or key got into the free space between the tank and the drum, and the element stopped rotating. In this case, operating the machine is not recommended, as the object may cause jamming or damage to the drum walls.In each case, the situation requires expensive repairs associated with replacing the internal parts of the machine.

It is easy to determine the presence of a foreign object in the tank. To do this, you need to open the loading hatch door and turn the drum manually first in one direction, then in the other. The presence of resistance, extraneous grinding or ringing will tell you that you are on the right track. All that remains is to remove the foreign object as quickly as possible, and this will require difficult actions, since you will have to work with the drain filter or the hole located under the heating element.

The first algorithm of actions is as follows:

- at the bottom right we find the hatch designed for draining;

- open its lid;

- spread rags on the floor;

- remove the trash filter;

- clean the body, sleeve, pipes.

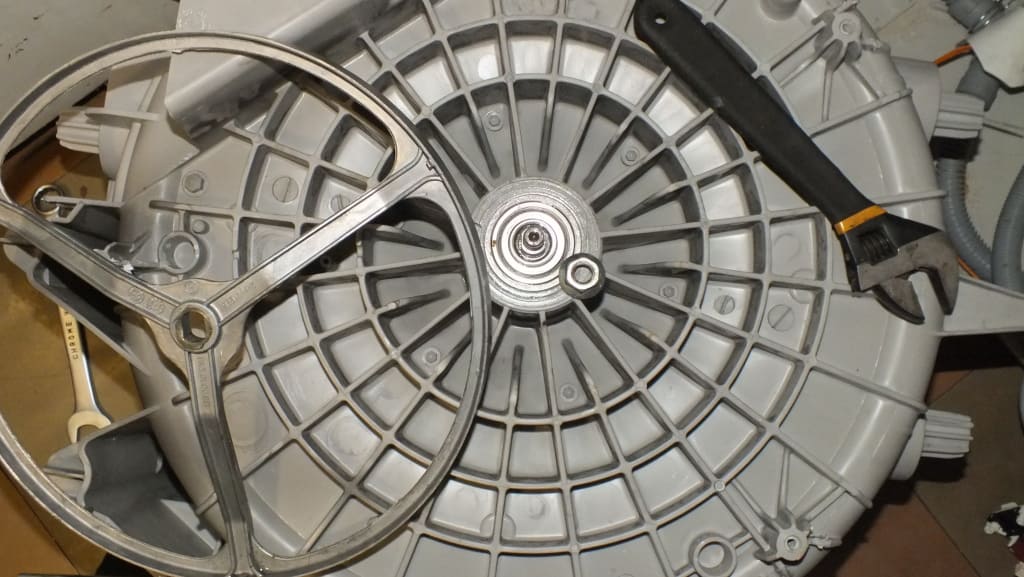

If the drum has stopped rotating and is completely jammed, the tank must be completely disassembled. We act as when replacing a bearing - we remove the panels from the top and back, dismantle the drive, electric motor, dispenser with module, counterweight elements, shock absorbers and other units of the machine. After completing this work, we take out the main tank, disassemble it and remove foreign objects. The difficulty arises if the tank of the machine is made in a non-disassemblable form. You will have to do four hours of sawing, and it is better to entrust such work to an experienced specialist.

Bearing problem

If the machine takes in water but does not spin the drum, the problem can be found in the bearings. Perhaps they have completely worn out, been knocked out, or the factory lubricant has been washed away. This situation is caused by improper loading of the tank with things, improper operation, and leaks in the seals. In each case it is required complete replacement of bearings, which is technologically quite difficult to accomplish:

- The washing machine is completely disassembled;

- the tank is removed;

- the drum is knocked out;

- failed bearings are obtained and new analogues are purchased;

- components and seals are replaced;

- all spare parts are fixed with waterproof glue and treated with sealant;

- The machine is assembled in reverse order.

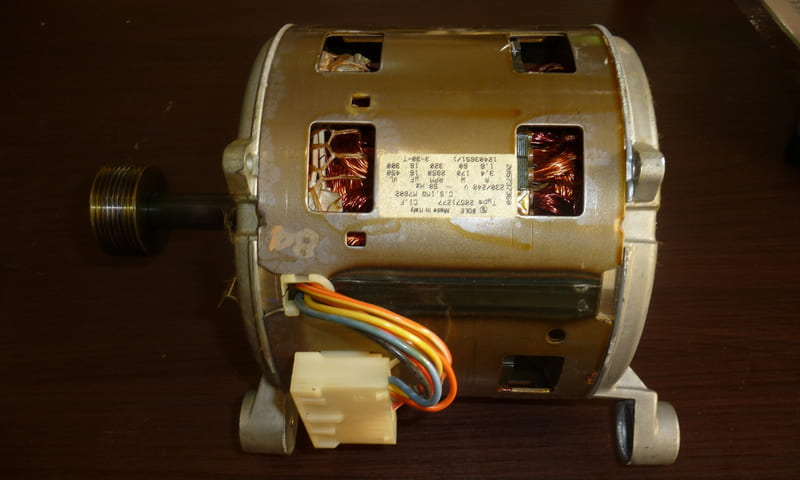

Electric motor failed

Often the drum stops rotating because for normal spinning the motor does not have enough power. And the main problem with this is worn brushes. To restore engine performance, you will have to:

- disassemble the body of the machine to gain normal access to the engine. To do this, you will have to remove the back cover and the drive belt;

- We disconnect the electrical wires connected to it from the motor;

- On the sides of the body we find brushes inside;

- Using a flat screwdriver, pry up the terminals and disconnect the wires;

- we shift the contact in the opposite direction;

- press the latch so that the spring relaxes, push out the brush;

- we measure the length of the tip, which should be at least seven to ten millimeters;

- We install new brushes in the motor traverses;

- we compress the springs and install them in their places;

- We screw the terminals and connect the power supply wiring.

The water heater burned out

In washing machines from Zanussi, the reason for the drum stopping may be a burnt-out heating element. The temperature sensor stops sending messages to the management system about liquid heating, and the module does not send a signal to the electric motor to increase speed. The engine rotates in test mode, making no more than three dozen revolutions in one minute. In a situation like this using a multimeter to check the serviceability of the heating element, if necessary, it is performed replacement with a corresponding analogue.

Testing is carried out as follows:

- the back cover of the washing machine is dismantled;

- there is a heating element installed below the tank;

- the multimeter is set to resistance testing mode;

- All wiring is disconnected from the heating device;

- We touch the contacts with measuring probes and check the readings.

Checking the electrical

Flying electronics may be another reason why the drum in a Zanussi washing machine stops rotating. But it is quite difficult to establish exactly that the problem lies in the board and what the need for repair work is.In addition, it often appears that the failure occurred in the control module, but in fact the reasons for the drum stopping are related to the faults discussed earlier and not completely eliminated. So electronic circuits should not be checked and repaired immediately - you may not achieve a result, and you will spend a lot of money on repairs.

Just invite an experienced specialist to your home so that he can diagnose your machine and accurately determine the reasons why the drum is unable to rotate. In addition, it is the master who can correctly repair a burnt-out triac or detect a failed contact.

Do not repair electrical wiring and chips yourself - you will finally break the board, and replacing it will require decent financial costs. similar entries from this section